Kayan kwayar cutar kwayoyin cutasuna da mahimmanci kayan don gas da rabuwa da ruwa da tsarkakewa a cikin masana'antu daban-daban. Su ne cranstalline metaluminosicatrating tare da pores uniform kwayoyin halittu dangane da girman su da siffar su. Damasana'antar masana'antar kwayar cutarYa ƙunshi matakai da yawa masu rikitarwa don tabbatar da samar da kayan ingancin ingancin da ke yin takamaiman girma da kuma kayan adon.

Samun siarewar ƙwayar ƙwayar ƙwayoyin cuta yana farawa tare da zaɓi na albarkatun ƙasa, ciki har da silicate na sodium, alumina da ruwa. Wadannan kayan suna hade ne da madaidaicin madaidaicin gel, wanda sannan ya sanya shi zuwa tsarin hydrothermal. A cikin wannan mataki, gel yana mai zafi zuwa babban yanayin zafi a gaban abubuwan alkaline don inganta samuwar wani yanki na kristal tare da suturar pores.

Wani muhimmin mataki na zamani a cikin masana'antar shi ne musayar ion musayar sodium, wanda ya shafi maye gurbin sodium ions a cikin crassstrit tsarin tare da wasu crass crystal tare da wasu crations tare da wasu crations kamar allium, potassium ko magnesium. Wannan tsari na musayar ion yana da mahimmanci don sarrafa kayan sieve, gami da karfin adsorption da kuma bukatar. Nau'in cation da aka yi amfani da shi don musayar ion ya dogara da takamaiman bukatun aikace-aikacen na sieve sieve.

Bayan musayar ion, siice kwayoyin kwayar cutar kwayar cuta da bushewa don cire kowane impurities da kuma sharri sinadarai daga tsarin samarwa. Wannan yana tabbatar da cewa samfurin ƙarshe ya cika ka'idodin tsararrun ƙa'idodin da ake buƙata don aikace-aikacen masana'antu. Bayan wanka da tsarin bushewa sun cika, ana kirjin kwayoyin halitta a babban yanayin zafi don daidaita tsarin kristal kuma cire duk wani mahimman mahadi.

Mataki na ƙarshe a cikin tsarin masana'antu ya shafi kundin sidove na kwayoyin halitta don shirya su don aikace-aikacen adsorption. Wannan tsarin kunnawa ya ƙunshi dumamasieve sieveA yanayin zafi mai girma don cire danshi da haɓaka kayan adsorction. Tsawon lokaci da zazzabi na kunnawa ana sarrafawa a hankali don cimma girman pore da ake so da kuma yanki na sieve na sieve na kwayoyin.

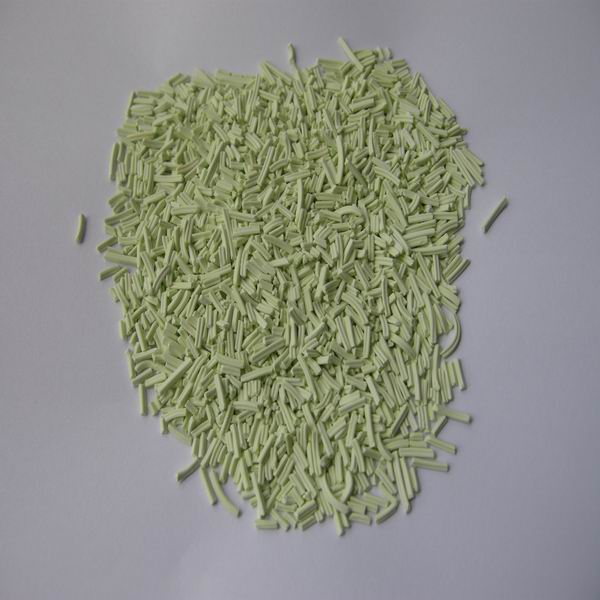

Ana samun sida na kwayoyin cuta a cikin girma dabam dabam, ciki har da 3A, 4A da 5a, kowaceakai, kowanne ya dace da takamaiman aikace-aikace. Misali,3A kwayar cutar kwayoyinana amfani da shi sau da yawa don narkewar gas da taya, yayin da4a da sie mara amfani da kwayoyinAn fifita kwayoyin halittar kwayoyin da cire ƙazanta kamar ruwa da carbon dioxide.

A taƙaice, masana'antar kwayoyin cuta ta kaddamar da ita ce hadadden tsari wanda ya shafi abubuwa masu yawa, musayar ion da kuma wanka, bushewa, ƙididdigewa. Wadannan matakai suna sarrafawa sosai don samar daKayan kwayar cutar kwayoyin cutaTare da kayan kwalliyar al'ada da kuma pore girma ga da bambancin bukatun masana'antu kamar man fetur, magunguna da sarrafa gas. Babban inganciSieve kidan kwayar halittaTa hanyar masu da aka gabatar suna taka muhimmiyar rawa wajen cimma matsaka da ingantaccen tsari da tsarkakewa a aikace-aikace daban-daban na masana'antu.

Lokaci: APR-19-2024